|

|

i am reworking my front suspension. i built these axles about 6-7 years ago so i built them cheap and kinda ghetto. i sold the 9"s out from under it and replaced them back with these. its not going to be a offroad machine just a cool rig for the family to drive around in and such.

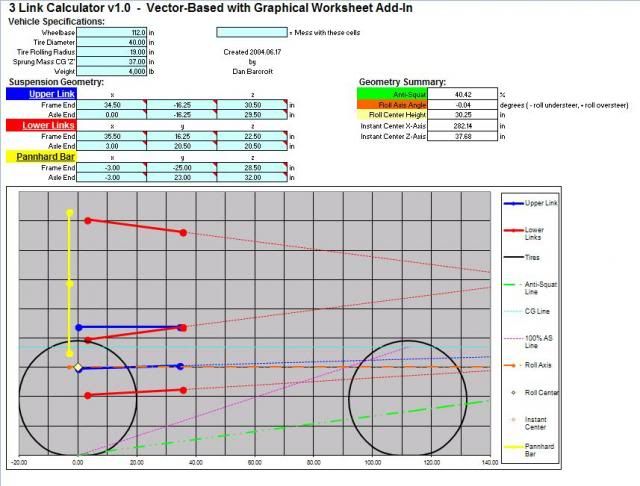

thats what i am comming up with. ive read a few places that to shoot around 50% for a DD/trail rig is that correct?

Find the version of the calculator that allows you to calculate the pinion angle change during bump/droop. The relative lengths of the upper/lower arms look like the pinion angle may get angry at full droop.

I'll let others that have designed their suspensions chime in on the rest of the numbers. But that said...

I'm looking into 3-linking my front as well and with as much as I love the math/science behind everything, those calculations are just too dependent on the CoG height -- which (for me at least) is nothing more than a ballpark guess. So my plan is to focus on the parameters I know I can control (such as pinion angle change and where I actually can put my mounts), then try to add in multiple mounting holes for the upper control arm to allow for adjustability.

Last edited by SirFuego; 03-22-2013 at 04:15 PM.

I agree with that. I had an "idea" when I did my rear and it came out great. Drivability is awesome. I know things will change once you get into it.

One thing I can add is to you will want to in board your lower links on the frame side so the link can clear the frame on bump. I didn't do it enough as I wasn't to build my setup with the jeep torn apart in the garage. Good luck on your build!

The calculator is really best to see what moving mounting points around will do and help understand the effects different ideas might have and how different adjustments play together. In a preexisting vehicle, there's generally too much to work around to really get anything dialed by the calculator, so you really end up applying "ideals" to your application as best you can.

Make the upper as close to horizontal as possible with as much vertical separation as you can get. Keep the lowers as flat as possible, too. This will keep the instant center reasonable and prevent wheel hop like you see with radius arms. Make the frame side lower mounts closer together than the axle side to minimize roll oversteer. Some say it doesn't matter, but I feel that keeping the lower axle-side mounts below axle centerline helps combat brake steer, especially if there's any give in your joints/ bushings. Try to keep the upper and lowers close to the same length to prevent excessive pinion movement. If you're using a standard U-joint driveshaft, you'll want the pinion angle to stay fairly constant throughout travel. If you're running a double cardan joint at the t-case, you want a slightly longer upper if possible to keep the pinion pointed at the t-case. In all reality, unless you're racing you won't be moving fast enough in 4wd to cause vibes either way, but you do want to prevent binding.

For the panhard, the higher the better for a tall/ lifted rig IMO. The higher the panhard in a 3 link w/ panhard generally exclusively controls the roll center at that end of the vehicle. The higher the roll center, the less body roll you will have, but the less bite you will have at the vehicle's limits. Both of these are good in something with a tall COG, especially when off camber. Think of roll center as roll stiffness resulting from the geometry of your suspension. I prefer for front roll center to be higher than the rear if there is going to be a difference because this makes the entire vehicle more naturally prone to understeer at/ near its limits rather than oversteer (and spinning out). Of course, this is a matter of opinion and my preference - yours may vary.

edit: Don't forget to make the panhard as close in angle and length to the drag link as possible.

Last edited by IndyZJ; 03-24-2013 at 12:39 AM.

Here's how my numbers ended up:

Lowers: 24.5", upper: 26.5", 6" separation at the 'frame', 6.5" at the axle. LCA's mounts at the axle are ~36" apart and directly behind the tube, and ~34" apart at the 'frame'. I don't remember the panhard length right now, but I wish it was longer(haha). So far I'm very happy with it, it's tracks straight down the highway, has almost zero brake dive, no brake steer and can easily out-do my coils/12" shocks. I had a chance to get it up to 30-35MPH in the dirt/snow and it handled it very well, it was super predictable and easy to control. So far I haven't had any weird wheel hop or unloading issues either. Hope that helps you some.

Thanks for the input y'all I've been doing lots of research and reading. My thing is I don't think I am wrapping my head around brake dive. Is it how the axle rolls when I apply the brakes?

Someone correct me if I'm wrong but I think brake dive is how the anti squat comes into play on the front suspension . So the higher the anti squat the more resistant to brake dive. But having a bunch of anti squat would be foolish for when you're wheeling and get a bunch of wheel hop.

With that said I'm in the ball park of 70-90% depending on where my cog truly is and don't experience brake dive what so ever. The jeep behaves better than with it did with short arms

Ah gotcha. I am guess the anti squat opposes the front axle twisting when the brakes are applied?

From what I gathered reading threads on pirate over and over. 4 basic rules I went by.

1. Flat and parallel lowers.

2. Ample separation at the axle and frame side. I am running 10" at both the frame and axle.

3. Tall as reasonably possible trackbar. I run full hydro so I didn't have to worry about matching my tie rods. In this case I made my axle side mount taller than my frame side. If I understood this correctly this increases stability at speed. Something I am shooting for in my design as I want to travel at highway speed.

4. Lower links as wide apart as possible without limiting steering. My tires will rub the arms at full turn.

All of my links are out boarded at the frame side. This is on my CJ8 but wish I had run the same setup on my Zj when I had it. Rig sits 21" at the frame with 40's at ride height. Low and stable is what I am shooting for. I hated the way my ZJ worked and I always wished it was about 5" lower.

Here you go. I have three holes on my frame side upper for adjustment. You can see how these change the anti-squat/anti-dive. If I am undertsanding this correctly having a negative roll axis is desireable. I may raise my lower axle links .5"...

Middle Hole:

Lower Hole:

Upper Hole:

i shoot for the roll axis to be 0 and the roll center to be as high as possible. from there you want to make sure your pinion angle does what you want during full travel.

all the while keeping the anti-squat from 80-120. anti-squat changes so much with tire size and how much weight you have in the back. i used to pay a ton of attention to AS now i just get it close.

| « Previous Thread | Next Thread » |

| Thread Information |

Users Browsing this ThreadThere are currently 1 users browsing this thread. (0 members and 1 guests) |