|

|

Because I need another project like I need a hole in the head, I've decided to build a CNC plasma table. In what has got to be one of my biggest come ups, I got a free Fanuc Power Mate CNC controller, pendant, drives and servos from my work. We've upgraded about a dozen machines from Power Mates to newer CNCs, so they are just sitting around. My project manager said I could have one; these things cost 20K+!

I'm in the middle of buying a house right now, so this thing is going to take quite a while to complete. I'm going to build an encolsure to house the electronics and then put it away until I'm done moving. I'm planning on a 2'x3'ish work envelope.

For now I just got the parameters setup on the CNC and the fiber optic link to the PC working.

Last edited by downtowncb; 07-07-2012 at 01:07 AM.

did you get the updated program aswell? i know some of the programs are 20k. but that might be on the machines that cost 150k

These particular CNC's are normally run "headless" from a server without a display, that's why the interface is pretty basic. In its native form it will do everything I could want, but down the road I may write a custom fancier interface. The machine this CNC came out of cost over 500K, to give you some idea. I write all the software that tailors these CNC's to the machines we build every day, so it will be easy for me to customize it to my simple 3 axis table.

Last edited by downtowncb; 07-07-2012 at 01:30 AM.

Reason #4573 I should have gone into engineering. The only stuff we have sitting around, up for grabs are body parts.

This looks like an awesome project. Have fun!

Ya, I'll take mechanical parts over body parts lol. What do you do?

This was just an amazingly lucky circumstance that we have these and have no use for them. They could sell them back to Fanuc and they then refurbish them, but it's not worth the time. I got lucky with these drives too. All the machines we build to run off 3 phase 480V, which we then step down to 3 phase 240V using a transformer; not something you normally have in a home. I figured I was going to have to buy a phase converter, but I read through the data sheets on these drives last night and they are small enough that they can run off of normal single phase 240V, just like my welders. Sweet, one less thing to buy!

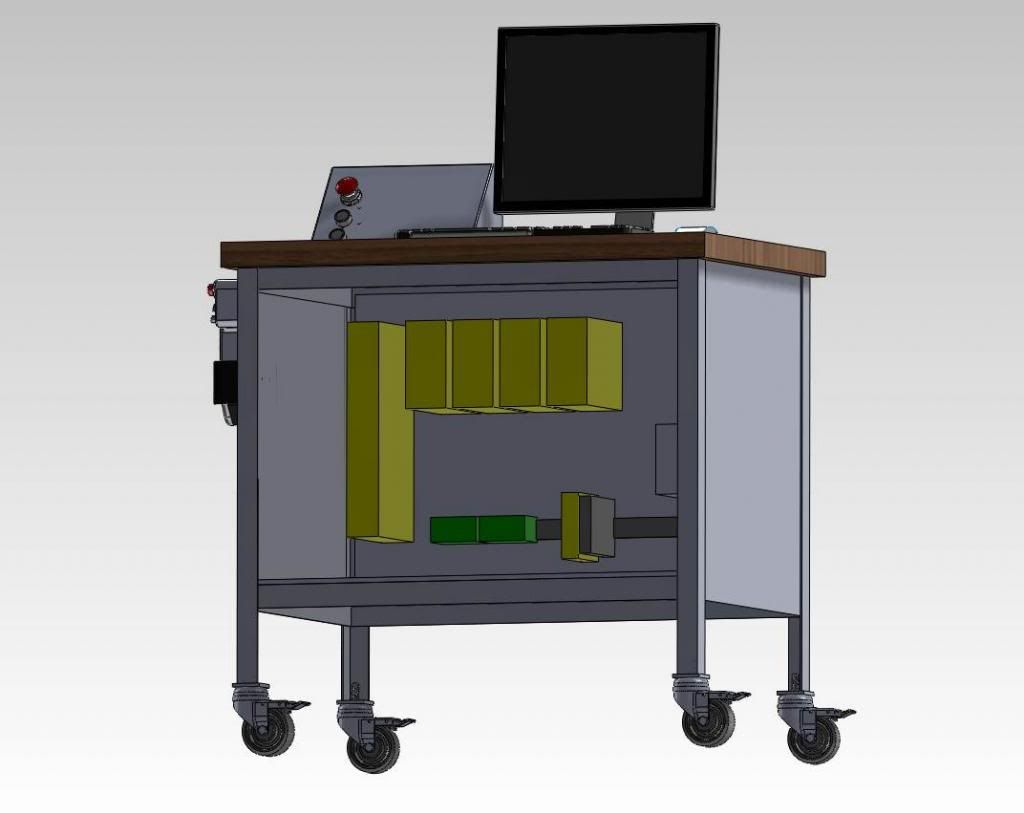

Starting to work on the control cabinet this weekend, nothing exciting to show yet, just cutting out materials, but I figured I'd show the model of what I'm building.

I'm building the whole cabinet from scratch. I found one close on McMaster that I liked, but it wasn't enclosed and it wasn't cheap so I just decided to build exactly what I wanted. This will house the CNC and PC and will have a connectorized umbilical to connect to the plasma table.

Whats with the cabinet door handles? Hinged in the middle?

what are you using for arc/heigh control?

this is a cool project. i've been forced to learn alot about CNC over the past few months. once you get into it there really isn't that much. do your self a favor and build the gantry from steel don't use that shitty extruded aluminum profile.

have you ever seen the plasma tables that hold the sheet at an 80 degree angle. you can fit a 4x8 cutter in 3' of floor space. makes a pretty rad garage set-up.

It will have a Z axis with 6 inches of travel. I don't have arc height control fully designed yet, but the CNC has Profibus that you can hook an analog input module up to. So you could take the proportional arc voltage output from the plasma cutter and vary the Z axis position using it. The capabilities are all there, it will just take a little programming.

Why do you say build the gantry from steel instead of extruded aluminum, that's exactly what I was planning haha?

No I've never seen a table like that, sounds pretty interesting. Though I am planning on making it a water table.

Last edited by downtowncb; 12-17-2012 at 02:08 AM.

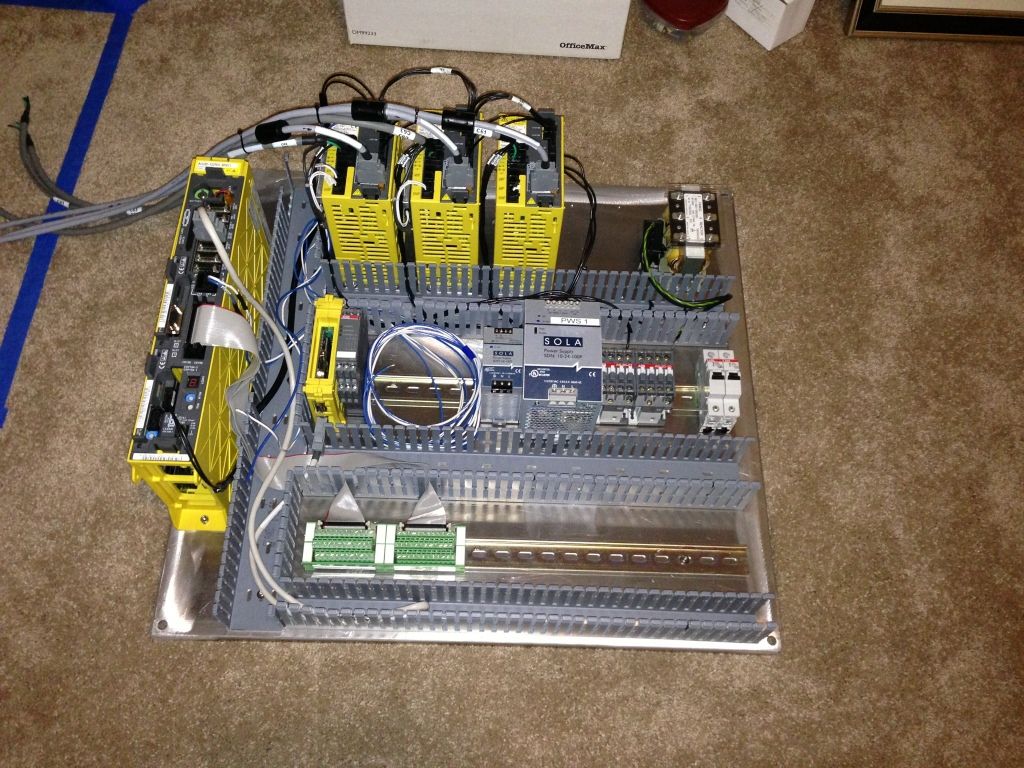

Progress on the cart. The aluminum plate is going to be the mounting plate for the electronics, the sides will be enclosed with sheet metal and it will be powder coated.

Made some progress on wiring it up, more to come on Saturday.

Wiring is 95% done. Now I just need to finish up the control cabinet and get it off to powder coat.

im damn glad you can wire these things up, because they look a wee bit cofusin.....lol, good job man.

This is pretty simple actually, because I work on these systems every day. Below is a picture of a Flex Track, it's a machine that adheres to aircraft under construction using suction cups and drills out holes and installs fasteners. I program these. The CNC I'm using to control this table came from a much older version of one of these guys. That's not me btw.

I finished the umbilical today. This is 12' long and will connect the controller to the table.

The aluminum stuff moves and wiggles unless you run it slow. I guess it depends on the weight of your cutting head, the speed you want to run, and the size of the aluminum profile you get.

If I was building a table. I would use it. It seams to be the easiest way. But in the long run you will have a better product.

Eitherway you have a wicked build going on

Finally got some time to work on the cabinet. I decided to change from the slider doors to piano hinges.

Last edited by downtowncb; 07-16-2013 at 01:03 AM. Reason: updated picture links

I said this was going to be slow right? Well one year later and the control cabinet is pretty much done.

I also got another come up from work, they're shutting down our in house weld shop and selling off all the welders, so I bought a Thermal Dynamics PakMaster 100XL. This thing is WAY more powerful than I was ever planning on but I got it and a lifetime supply of consumables for $500! It also has the CPC style connectors that Hypertherm uses to interface with a CNC, so I don't have to hack the torch to get remote start and arc transfer signals.

Now for the table...

Gawd its a sexy cabnet, annnndddddd i hate you.

Did not read the whole thread but how many bucks did it set you back? And are you planning on a shop or is this weekend fun?

I'm into the whole project for $900 so far, $500 of which was for the plasma cutter. I got the CNC, drives, and servos all for free from work. They were leftovers after an upgrade we did on a customer's machine. It's not the latest and greatest technology, but it will run a plasma table no problem.

I may try to monetize a small return on the table, offer up some cutting services, but I built it just for personal use. I'm also building it with an interchangeable router head so I can mill MDF and other soft materials.

| « Previous Thread | Next Thread » |

| Thread Information |

Users Browsing this ThreadThere are currently 1 users browsing this thread. (0 members and 1 guests) |